The film about this demonstrator is here

Factory of autonomous Products

Demonstration Scenario

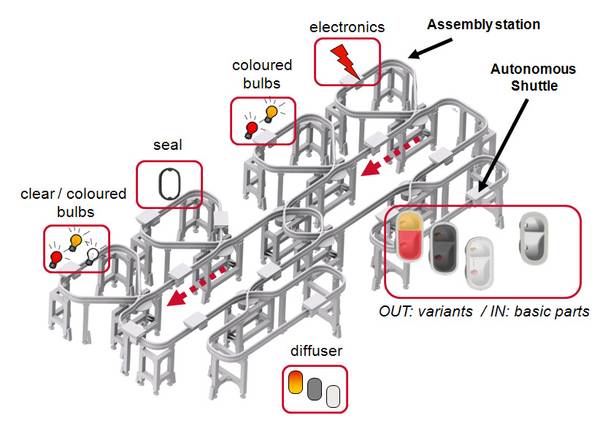

The current demonstration scenario starts with ten customer orders for rear lights with a black diffuser. During processing five of these orders will be canceled and five rear lights with clear diffuser and five with colored diffuser will be ordered. Thus, some products change their target variant to prevent an overproduction. In addition, a workstation breaks down. The products react independently on this event and try to avoid this workstation. Either they change the sequence of the process steps and come back later when the workstation is fixed or they take an alternative workstation. In this way the products reduce their processing time.

- Presentation of the "Factory of autonomous Products" 2010

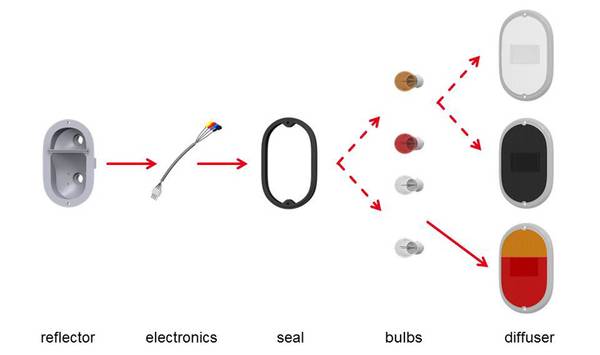

Elements of the demonstrator

Summary

- Presentation of the "Factory of autonomous Products" 2012