The film about this demonstrator is here

Automobile Logistics

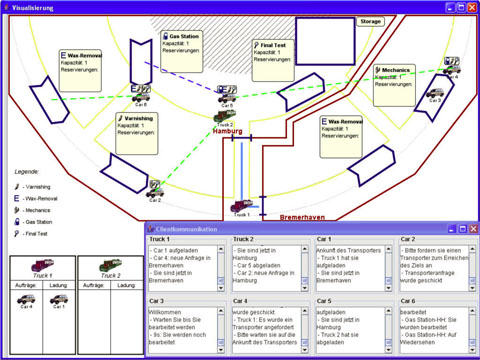

The availability of information on states, locations, capacities, surrounding conditions, and the correlation between these pieces of information are essential for the realisation of autonomous processes within automobile logistics. In this environment RFID technology can establish a relationship between an object and the context it is in. The locality of automobiles and transporters determined at the processing stations and important route sections is achieved by linking this information with the physical logistical object within the demonstrator. Besides IDs, the RFID tags also store information on the sequence, number and type of processing steps, as well as on due dates for individual automobiles. A UHF system is used to obtain greater read/write distances, and thus increased flexibility of the RFID system.